Case Study

Digitization of customs processes with Digicust at Wackler Spedition & Logistik

Wackler Spedition & Logistik is a family-run company with a tradition of over 175 years. The medium-sized logistics company based in Göppingen near Stuttgart is currently managed by the fourth generation of the Schwarz family, while the fifth generation is already waiting in the wings. Since its foundation in 1993, Wackler has been a corporate member of CargoLine, a cooperation of medium-sized freight forwarders. By continuously adapting its portfolio to market requirements and investing in its fleet, machinery and employees, Wackler has succeeded in establishing itself as a first-class provider of national and international transport solutions. With its extensive logistics portfolio, which ranges from warehousing and full-service logistics to e-commerce solutions, Wackler Spedition & Logistik offers its customers tailor-made solutions. The introduction of Digicust's automation solution led to excellent results within just 7 weeks. Initially, 14 T-papers were processed per week with an average of 25 items per document. In this short time, it was possible to automate the processes smoothly - a remarkable success, especially as the project was implemented at two locations. An important milestone was the complete automation of 2,000 export declarations in just one month. At the same time, 14,000 transit declarations were successfully automated during the three-month project period. This means that a total of 16,000 customs declarations were automated within just a few months. Another advantage of the system is evident for future customers: Each new shipping registration can be fully automated within just two weeks. With a view to 2025, there are also plans to train the system for all customer cases.

Customs processing in the focus of digitalization

Processing time reduced by 64%

Marc Fiegert, Head of IT at Wackler Spedition & Logistik, is driving forward the digitalization of customs processes. An important reason for the introduction of the Dexter IDP solution from Digicust was the new ATLAS Release 9.1, which places new requirements on the creation of T-papers. Prior to the introduction of Digicust, around 14 T-papers were created manually every week, which took a considerable amount of time - around 39 working hours.

The automation of customs processes with Dexter IDP made it possible to drastically reduce the personnel effort to just 14 hours per week. The digital recording of goods tariff numbers eliminates the manual recording of individual items. This leads to considerable time savings and a significant minimization of error sources.

The future of customs in a digital world

Fiegert sees the future of customs in an increasingly digitalized world as automated and transparent. Standardized documents such as the Movement Reference Number (MRN (customs declaration)) should be transmitted without manual effort, as the information only needs to be passed through. Key figures that speak for themselves

Customs clearance in the focus of digitalization

Automation strengthens customs provider

Increasing automation also has an impact on the role of traditional providers of customs services. The digitalization of customs processes can reduce costs and strengthen the competitiveness of service providers. However, the implementation of automation solutions is a challenge, especially when it comes to adapting existing customs processes and taking into account the different requirements of customers. Automation enables faster and more efficient customs clearance, reduces costs and improves compliance with regulations. The digital networking of all companies and authorities involved in the transport chain plays a crucial role in avoiding delays and making information available early and transparently.

Why Digicust?

The decision to use Digicust's Dexter IDP solution was a logical step for Wackler. The AI-based web application significantly optimizes customs processing by automatically filling out customs declarations from various data sources and minimizing the error rate. Another key benefit is the automatic assignment of customs tariff numbers based on the goods description, which ensures the consistency and accuracy of customs clearance.

Vision and outlook

Efficiency through digital customs clearance

Marc Fiegert's vision is to further revolutionize customs clearance by making processes more efficient and transparent in order to facilitate international trade and increase the company's competitiveness. His wish would be to standardize and automate the customs process worldwide to completely eliminate manual, error-prone tasks and enable faster and more accurate processing. Overall, the case study shows how the digitalization of customs processes at Wackler Spedition & Logistik has led to a significant increase in efficiency. By using Digicust's Dexter IDP, Wackler was not only able to reduce personnel costs, but also improve the accuracy and speed of customs clearance - a decisive advantage in an increasingly digitalized and globalized logistics world.

Comment Borisav Parmakovic - CEO, Digicust "Wackler Spedition & Logistik impressively combines tradition and future: over 175 years of experience and now as a pioneer of digital customs clearance. Thanks to everyone who is driving this transformation forward with us!" Comment Marc Fiegert - Head of IT, Wackler We look back with pride on the remarkable journey of Digicust. This project has not only revolutionized our digital processes, but has also shown what is possible through dedicated teamwork and visionary leadership. From the initial idea to the successful implementation, we overcame challenges together and developed innovative solutions. Special thanks go to everyone involved, whose tireless efforts and expertise have contributed to the success of Digicust. Digicust is more than just a project - it is a symbol of our joint success and our ability to actively shape the future.

What We Do

Our solutions help companies do better customs clearance.

Solutions

Easy-to-implement end-to-end solutions for digital customs.

Scenarios

Our solutions are tailored towards your specific needs.

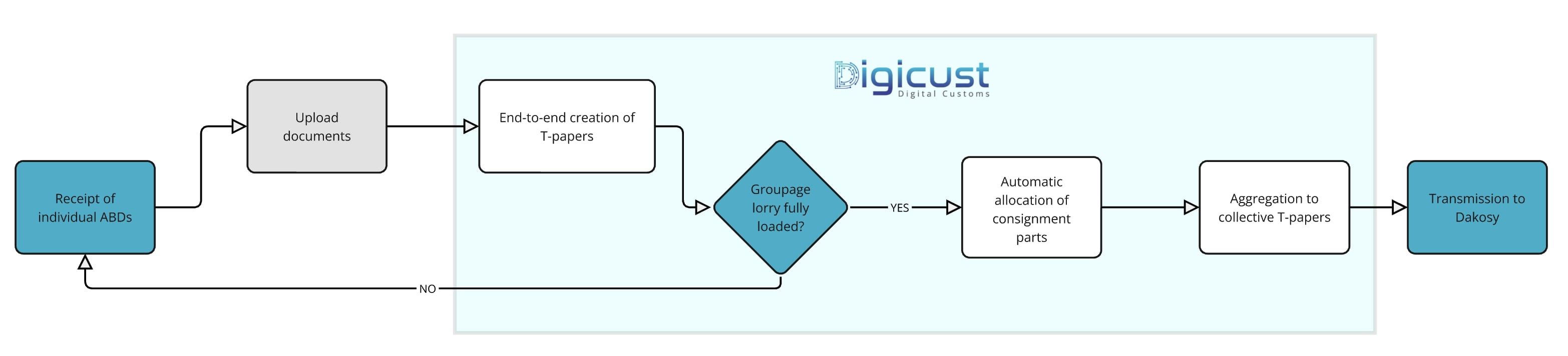

Digital Customs Scenario

Digicust aims to significantly reduce costs and time-consuming tasks while enhancing service quality. This will be achieved through the development of an AI-based web application, Digital Customs, which integrates virtual customs robots. The key features include:

- Smart Customs Declarations (Dexter IDP): Automated customs declarations.

- Smart Customs Documents (Neo): Automated document examination and requests.

- Customs Code Classification (Taric): AI-driven code classification.

- Automated Processes: Safe, green, and explainable customs clearance.

- Paperless Operations: Digital data management without manual entry.

- Internet of Customs: Interconnected systems along supply chains.